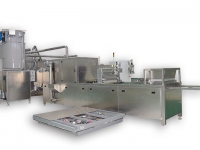

Automatic mogul line

- System for filling trays with starch

- System for removing excess starch

- System for tray transportation

- System for stamping products

- Feed tank for mass

- Heating system

- Automatic depositor

- Automatic system for tray input

- System for the final sprinkling of starch

- Container with wire mesh for dusting

- Container for starch filling

- Form prints customized

- System for product transportation directly to enrobing machine, length 4m

- System for process control via PLC

- Control via a touch screen

- Automatic starch feeding

- Automatic tray feeding

- Automatic tray tracking

- Automatic positioning and stamping in starch

- Automatic liquid mass depositing

- Automatic final sprinkling of starch

- Automatic tray removing

- Automatic products dusting (turning mechanism, 360° in two tacts)

- Automatic lifting tray mechanism (180° per tact)

- Simply mold for imprint change

- Quick product change

- Variable volume of deposit and speed

- Optional multiple color products

- Accurate deposits without tails with no chains used for transport of trays

- Program for each product and work via PLC

Technical specification

Capacity: from 8 to 15 trays/min

Material: stainless steel